-

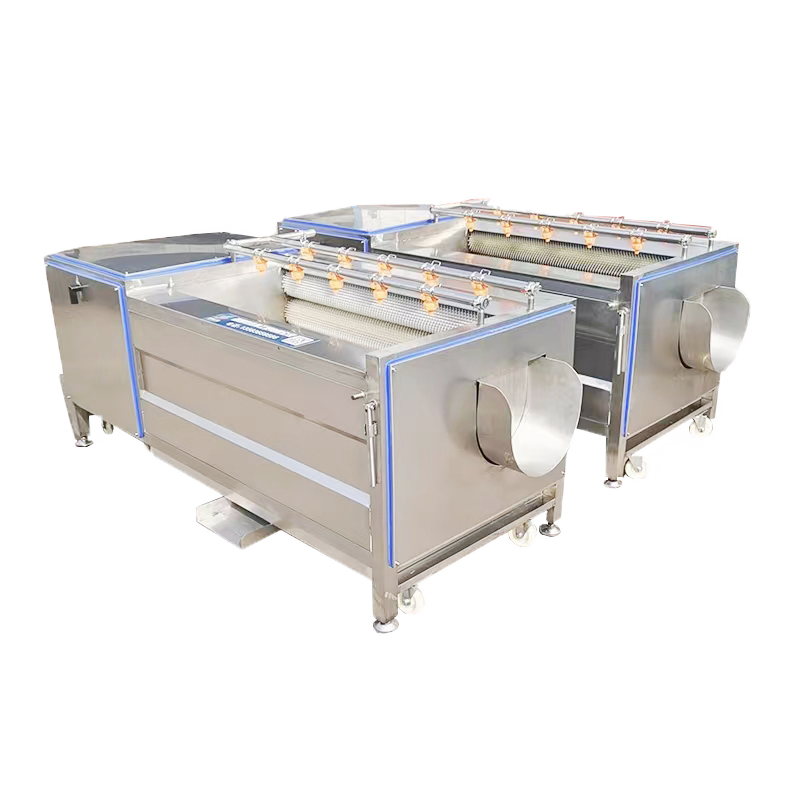

U-Shaped Brush Roller Cleaning Machine

U-Shaped Brush Roller Cleaning Machine is a specialized industrial solution for efficient preliminary cleaning of food materials. Engineered with a U-shaped trough and rotating brush rollers, it combines mechanical friction and water flushing to remove soil, debris, and biofilm from surfaces. Ideal for nuts, fruits, vegetables, and seeds, this machine ensures high cleaning efficacy while minimizing product damage. Constructed from food-grade stainless steel (SUS304/316L), it meets strict hygiene standards, with a user-friendly design enabling easy operation, maintenance, and sanitation. Its robust build guarantees long-term reliability, making it an essential asset for food processing facilities worldwide.

-

0.000.00

-

U-Shaped Brush Roller Cleaning Machine is a specialized industrial solution for efficient preliminary cleaning of food materials. Engineered with a U-shaped trough and rotating brush rollers, it combines mechanical friction and water flushing to remove soil, debris, and biofilm from surfaces. Ideal for nuts, fruits, vegetables, and seeds, this machine ensures high cleaning efficacy while minimizing product damage. Constructed from food-grade stainless steel (SUS304/316L), it meets strict hygiene standards, with a user-friendly design enabling easy operation, maintenance, and sanitation. Its robust build guarantees long-term reliability, making it an essential asset for food processing facilities worldwide.

Product Details

Working Principle

Raw materials enter the U-shaped perforated conveyor trough, where rotating brush rollers agitate and scrub their surfaces. Simultaneously, clean water sprays onto the brushes and trough, flushing away detached contaminants. The inclined trough design promotes automatic sludge discharge, while the conveyor belt moves materials forward for continuous cleaning. Optional frequency conversion allows adjusting brush speed to suit different product textures and cleaning requirements.

Features

Innovative U-shaped Design:

Maximizes cleaning coverage, reduces material residue, and saves floor space.

Adjustable Brush Rollers:

Adapts to various sizes (e.g., small seeds to large vegetables) for customized cleaning.

Food-Grade Materials:

Built with SUS304/316L stainless steel, ensuring corrosion resistance and hygiene compliance.

Automated Operation:

Reduces labor dependence, with intuitive controls for efficient workflow.

Energy Efficiency:

Optimized motor and water recirculation systems (optional) minimize resource consumption.

Technical Highlights

Crafted from premium stainless steel, the frame ensures structural stability and easy cleaning.

The drive system uses high-torque motors and precision bearings for smooth brush rotation, while sealed electrical components prevent water ingress.

Modular design facilitates quick disassembly for maintenance, and optional upgrades (e.g., variable-frequency drives, water filtration) enhance versatility.

Compliance with international safety and sanitation standards (e.g., CE, NSF) ensures global market adaptability.

Application Fields

This machine is ideal for preprocessing in food manufacturing, handling:

Nuts & Seeds: Almonds, cashews, peanuts, sunflower seeds, pumpkin seeds.

Fruits & Vegetables: Potatoes, carrots, apples, cucumbers, leafy greens.

Grains & Pulses: Beans, lentils, and cereal grains requiring surface decontamination.

By removing dirt, pesticides, and microbial buildup, it enhances product quality, food safety, and processing efficiency in industries like snack food, canning, freezing, and ingredient manufacturing.

vAll machines can be customized to meet your specific requirements. Contact us for more details!

.png)

.png)

.png)