-

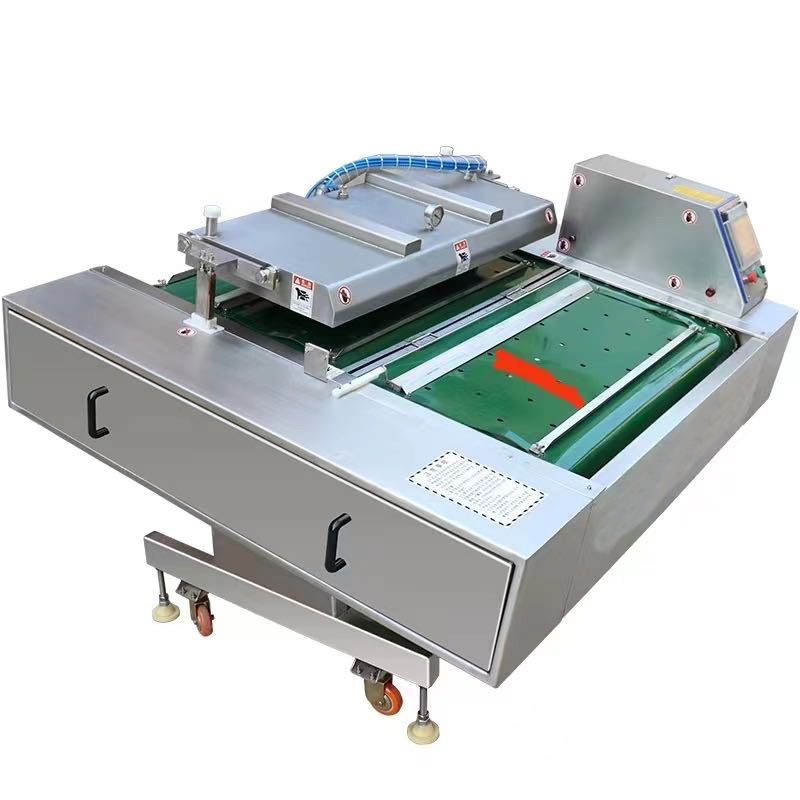

Rolling Packaging Machine

Rolling Packaging Machine is a high - efficiency automated solution engineered for continuous roll - film packaging in the food industry. With a stainless - steel frame and precision - controlled components, it integrates film unrolling, product forming, filling, sealing, and cutting processes seamlessly. Capable of handling diverse food items such as snacks, powders, and liquids, the machine guarantees consistent packaging quality while adhering to hygiene standards. Its user - friendly interface and reliable performance make it perfect for exporters looking to satisfy international market demands, thus boosting productivity and dependability in packaging operations.

-

0.000.00

-

Rolling Packaging Machine is a high - efficiency automated solution engineered for continuous roll - film packaging in the food industry. With a stainless - steel frame and precision - controlled components, it integrates film unrolling, product forming, filling, sealing, and cutting processes seamlessly. Capable of handling diverse food items such as snacks, powders, and liquids, the machine guarantees consistent packaging quality while adhering to hygiene standards. Its user - friendly interface and reliable performance make it perfect for exporters looking to satisfy international market demands, thus boosting productivity and dependability in packaging operations.

Product Details

Working Principle

The machine initiates by unrolling roll film from a reel. A forming tube then shapes the film into a tube, which is sealed longitudinally. After that, products (solids, liquids or powders) are introduced into the tube through a filling system. Transverse sealing and cutting are performed at predetermined intervals to produce individual packages. The whole process is automated, enabling continuous high - speed packaging with precise control over sealing and cutting to ensure uniform pack size and quality.

Features

Stainless - steel construction:

Facilitates easy cleaning and meets food hygiene requirements.

PLC control system:

Comes with a touch screen for intuitive operation, parameter setting and real - time monitoring.

Variable frequency drive (VFD):

Supports stepless speed adjustment to accommodate different product and packaging needs.

Automatic detection:

Monitors film deviation, missing products and faults, ensuring stable operation and minimizing material waste.

Robust sealing technology:

Creates airtight packages to extend product shelf life.

Modular design:

Simplifies maintenance and component replacement.

Technical Highlights

Core technologies:

PLC - based automation, servo - motor - driven precision motion control and constant - temperature heat sealing. These technologies ensure accurate film feeding, sealing position and pressure control.

Heat sealing system:

Utilizes advanced heating elements and pressure mechanisms to achieve strong, leak - proof seals on various film materials like BOPP, PET, and aluminum - foil composites.

Filling system:

Can be customized for volumetric, weigh - based or pump - driven modes to handle powders, particles, liquids and other food consistencies.

Application Fields

This machine is widely used in the food industry for packaging a variety of products:

Solid foods: Snacks (chips, cookies, candy), nuts, tea, coffee beans, flour, powdered milk, seeds, etc.

Liquid & semi - liquid foods: Sauces, beverages, syrups, etc.

It can also be adapted for non - food items like small hardware parts or chemical powders (subject to packaging material compliance), with its primary focus on food packaging to meet the export demands of international markets.

vAll machines can be customized to meet your specific requirements. Contact us for more details!

.jpg)

.png)

.png)