-

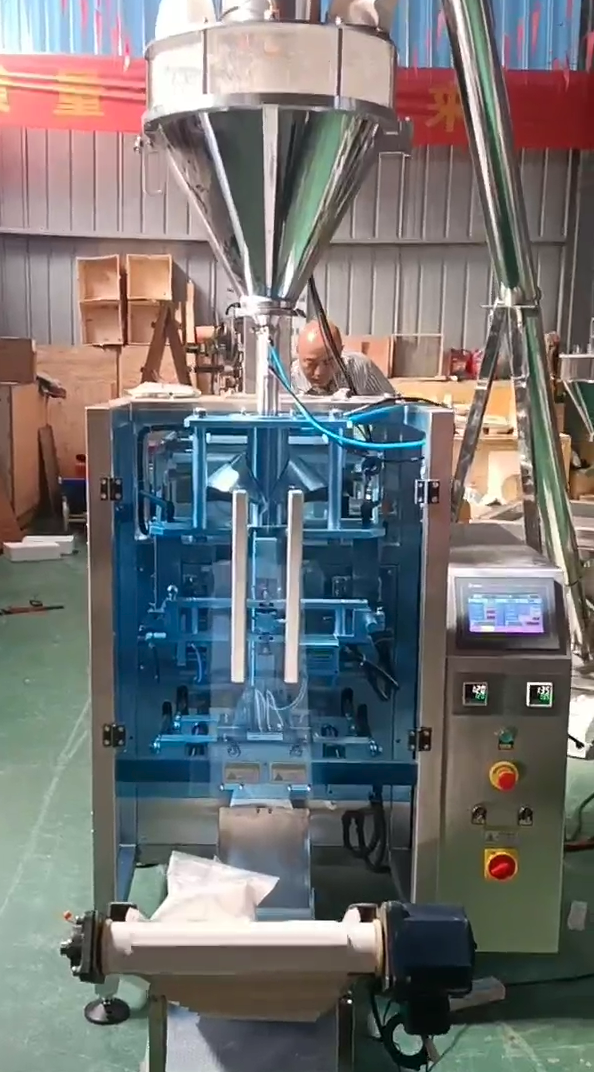

Powder Packaging Machine

Powder Packaging Machine is an automated vertical form-fill-seal (VFFS) solution engineered for efficient powder packaging in food, chemical, and pharmaceutical sectors. Integrating film feeding, bag forming, precision metering, filling, sealing, and cutting into a single workflow, it relies on PLC control for seamless synchronization. Constructed with food-grade stainless steel (304/316), it meets FDA/HACCP hygiene standards, while a 10-inch touchscreen interface simplifies operation. Capable of handling diverse powders (e.g., dairy powders, spices, chemical additives) at speeds of 40-60 bags/minute with ±0.5% dosing accuracy, this machine balances high efficiency and reliability for global markets.

-

0.000.00

-

Powder Packaging Machine is an automated vertical form-fill-seal (VFFS) solution engineered for efficient powder packaging in food, chemical, and pharmaceutical sectors. Integrating film feeding, bag forming, precision metering, filling, sealing, and cutting into a single workflow, it relies on PLC control for seamless synchronization. Constructed with food-grade stainless steel (304/316), it meets FDA/HACCP hygiene standards, while a 10-inch touchscreen interface simplifies operation. Capable of handling diverse powders (e.g., dairy powders, spices, chemical additives) at speeds of 40-60 bags/minute with ±0.5% dosing accuracy, this machine balances high efficiency and reliability for global markets.

Product Details

Working Principle

This vertical VFFS machine operates through a coordinated sequence:

Film Feeding & Bag Forming: Roll film passes through a guide system, shaped into a tube by a forming shoulder.

Positioning & Sealing: Photoelectric sensors detect pre-printed marks for precise bag alignment. A horizontal sealing jaw first seals the bag’s bottom; after filling, the top is sealed, and the finished bag is cut off.

Metering & Filling: An auger dosing system (single/double auger, variable pitch) meters powder by weight,适应不同流动性(free-flowing to slightly cohesive powders).

Control System: A PLC (e.g., Delta/Delan) + servo motor (Yaskawa) integrates all steps, ensuring real-time synchronization.

Features

Hygiene & Safety:

Full stainless steel (304/316) construction, compliant with FDA/HACCP; interlocked safety guards and emergency stop buttons.

Intelligent Operation:

10-inch HMI touchscreen for intuitive parameter setting (bag size, speed, weight) and recipe storage; inverter speed control (30-60 bags/min) for flexible production.

Precision & Efficiency:

±0.5% dosing accuracy via auger system; central lubrication reduces maintenance; quick-release guards enable easy cleaning.

Versatility:

Adapts to various powders (milk powder, coffee, spices, fertilizer, etc.) and packaging materials (BOPP/PE, PET/PE, aluminum foil films).

Technical Highlights

Core Technology:

PLC + servo motor drive ensures ±1% speed precision; auger dosing handles 5-3000g per bag.

Sealing Technology:

Constant-temperature sealing (0-400°C adjustable) with pressure control, compatible with laminated films.

Safety & Protection:

Overload protection and interlocked guards protect operators and equipment; IP65-rated electrical enclosure resists dust and splashes.

Application Fields

Ideal for industries where powder packaging is critical:

Food: Dairy powders (infant formula, milk powder), beverage mixes (coffee, tea), spices (paprika, black pepper), baking powders.

Chemical: Fertilizers (NPK), pesticides, detergent powders, food additives.

Pharmaceutical: Herbal powders, antibiotic powders (non-contact with drugs), and other non-toxic medicinal powders.

This machine combines automation, hygiene, and adaptability, making it a reliable choice for international clients seeking efficient powder packaging solutions.

vAll machines can be customized to meet your specific requirements. Contact us for more details!