-

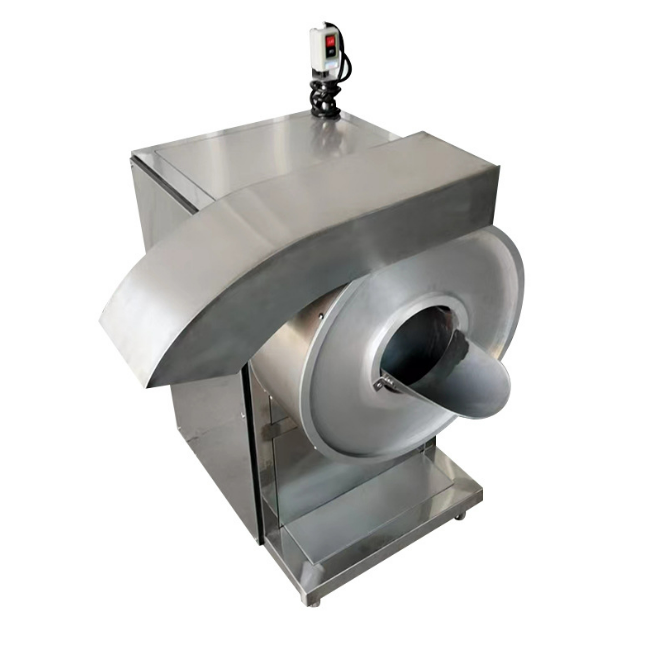

Strip Cutter

Strip Cutter is a specialized food processing machine engineered for efficient, precise cutting of materials like dough, chocolate, and other semi-solid foodstuffs into uniform strips. Constructed with food-grade stainless steel, it features a hygienic, easy-to-clean design that meets strict food safety standards. Equipped with advanced automatic control systems, the cutter allows for precise adjustment of cutting width, thickness, and speed, ensuring high-efficiency operation while maintaining consistent product quality. Its robust build guarantees durability and stability during high-volume production, making it an ideal choice for bakeries, confectionery factories, and other food processing enterprises seeking precision and reliability in strip-cutting operations.

-

0.000.00

-

Strip Cutter is a specialized food processing machine engineered for efficient, precise cutting of materials like dough, chocolate, and other semi-solid foodstuffs into uniform strips. Constructed with food-grade stainless steel, it features a hygienic, easy-to-clean design that meets strict food safety standards. Equipped with advanced automatic control systems, the cutter allows for precise adjustment of cutting width, thickness, and speed, ensuring high-efficiency operation while maintaining consistent product quality. Its robust build guarantees durability and stability during high-volume production, making it an ideal choice for bakeries, confectionery factories, and other food processing enterprises seeking precision and reliability in strip-cutting operations.

Product Details

Working Principle

The Strip Cutter operates through a mechanized process. Raw materials(such as dough blocks, chocolate slabs, etc.)are fed into the inlet. Driven by a motor-powered transmission system, the high-precision cutting assembly rotates at a preset speed. As the material moves through, the rotating blades slice it into uniform strips. The cut strips are then discharged through the outlet. Operators can control parameters like cutting speed and width via the control panel to ensure precise output.

Features

Hygienic & Durable Construction:

Built with food-grade 304/316 stainless steel, featuring a streamlined design for easy cleaning and compliance with food safety regulations.

Precision Technology:

Equipped with adjustable cutting mechanisms(width, thickness)and a PLC/touch-screen control system, enabling accurate dimension control and consistent strip quality.

High-Efficiency Operation:

Features high-speed cutting capability, low-noise operation, and energy-saving design, suitable for large-scale production.

Versatile Adaptability:

Can handle various materials(dough, chocolate, soft candy, etc.)and adjust parameters to meet different processing needs.

Technical Highlights

Cutting System:

Uses heat-treated, high-hardness alloy blades with sharp edges for clean, precise cuts.

Drive System:

Employs a stable gear/belt transmission system with overload protection, ensuring smooth operation and long-term reliability.

Control System:

Integrates an automated control module(e.g. PLC + touch screen)that supports parameter customization, program storage, and real-time monitoring.

Safety Features:

Includes emergency stop buttons and interlocked safety guards to ensure operator safety during operation.

Application Fields

Food Industry: Ideal for bakeries(cutting dough strips for bread, pastries), confectionery manufacturers(chocolate strips, candy materials), and grain processing plants(noodle strips, doughnut strips).

Other Fields: Also applicable to pharmaceutical production(cutting strips of medicinal materials)and certain material processing sectors requiring precise strip-cutting of soft materials(e.g. packaging materials, rubber sheets).

vAll machines can be customized to meet your specific requirements. Contact us for more details!

.png)

.png)