-

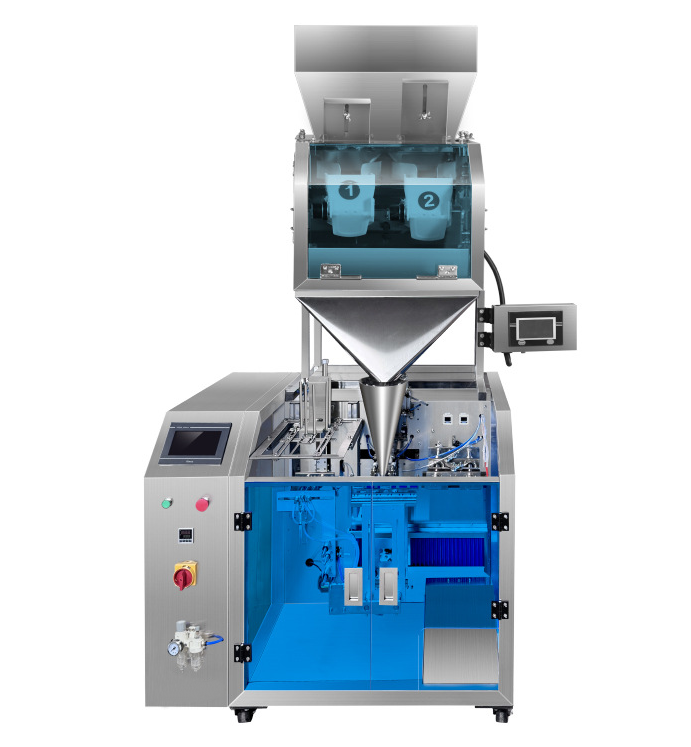

Bagged Granule Filling Machine

Bagged Granule Filling Machine is an advanced automated solution designed for precise and efficient packaging of granular materials. Ideal for food, chemical, agricultural, and industrial sectors, this machine combines high-speed filling capabilities with a high-precision weighing system to ensure consistent dosing accuracy. Constructed with high-quality stainless steel for durability and easy cleaning, it complies with international food safety standards. Equipped with a user-friendly PLC control system and touchscreen interface, it offers intuitive operation, recipe management, and seamless integration into production lines. Capable of handling various bag sizes and materials, it minimizes material waste and maximizes productivity, making it a reliable choice for global manufacturers seeking robust, efficient packaging solutions.

-

0.000.00

-

Bagged Granule Filling Machine is an advanced automated solution designed for precise and efficient packaging of granular materials. Ideal for food, chemical, agricultural, and industrial sectors, this machine combines high-speed filling capabilities with a high-precision weighing system to ensure consistent dosing accuracy. Constructed with high-quality stainless steel for durability and easy cleaning, it complies with international food safety standards. Equipped with a user-friendly PLC control system and touchscreen interface, it offers intuitive operation, recipe management, and seamless integration into production lines. Capable of handling various bag sizes and materials, it minimizes material waste and maximizes productivity, making it a reliable choice for global manufacturers seeking robust, efficient packaging solutions.

Product Details

Working Principle

Granular materials are fed from the main hopper into a precision weighing mechanism (e.g., a weigh hopper), where a controlled loading system (such as a screw feeder or vibratory feeder) managed by a load cell or weighing sensor fills the hopper to the target weight. Once the set weight is reached, the discharge valve opens, releasing the material into a pre-positioned bag below. Simultaneously, the next cycle begins as a new batch of material enters the weighing hopper. The filled bag is then conveyed to a sealing station or collection area via a dedicated transport system. This continuous cycle ensures efficient, accurate filling while minimizing material residue.

Features

Stainless Steel Construction:

Built with food-grade stainless steel for durability, easy cleaning, and compliance with international hygiene standards (e.g., FDA, CE).

Intelligent Control System:

Features a PLC + touchscreen HMI for intuitive operation, recipe storage (for quick format changes), and real-time production monitoring.

Versatile Compatibility:

Equipped with quick-change components to adapt to various bag formats (pre-made pouches, VFFS systems) and sizes, enhancing operational flexibility.

High-Precision Weighing:

Utilizes load cell technology to achieve weighing accuracy within ±0.2%-0.5%, ensuring consistent fill levels.

Ergonomic & Safe Design:

Low-noise operation, dust-proof enclosure, and accessible components for easy maintenance and hassle-free cleaning.

Technical Highlights

Weighing Technology:

Employs high-precision load cell sensors for dynamic/static weighing, ensuring accurate dosing even for free-flowing or irregular granules.

Automation Control:

Powered by a reliable PLC (e.g., Delta, Siemens) and an intuitive HMI touchscreen, enabling seamless process control, data logging (production stats, weight tracking), and real-time error diagnostics.

Drive System:

Servo/stepper motors drive feeding and discharging mechanisms, ensuring smooth, precise movements and energy efficiency.

Production Capacity:

Typically ranges from 20-60 bags per minute (adjustable based on material density and bag size), with options for customized configurations.

Power Supply:

Standard 380V/50Hz (compatible with 110V/60Hz for global markets) to meet regional electrical standards.

Application Fields

Widely used in multiple industries for packaging diverse granular materials:

Food Industry: Coffee beans, cereals (corn, wheat), granulated sugar, powdered milk, beans (mung beans, red beans), cereal granules, nuts.

Chemical Sector: Laundry detergent beads, fertilizers, chemical additives.

Agriculture: Coated seeds, feed pellets, animal rations.

Pharmaceutical & Industrial: Herbal granules, additives for manufacturing processes.

This machine efficiently handles materials with varying particle sizes, flowability, and bulk density, making it a versatile solution for global packaging needs.

vAll machines can be customized to meet your specific requirements. Contact us for more details!

.png)