-

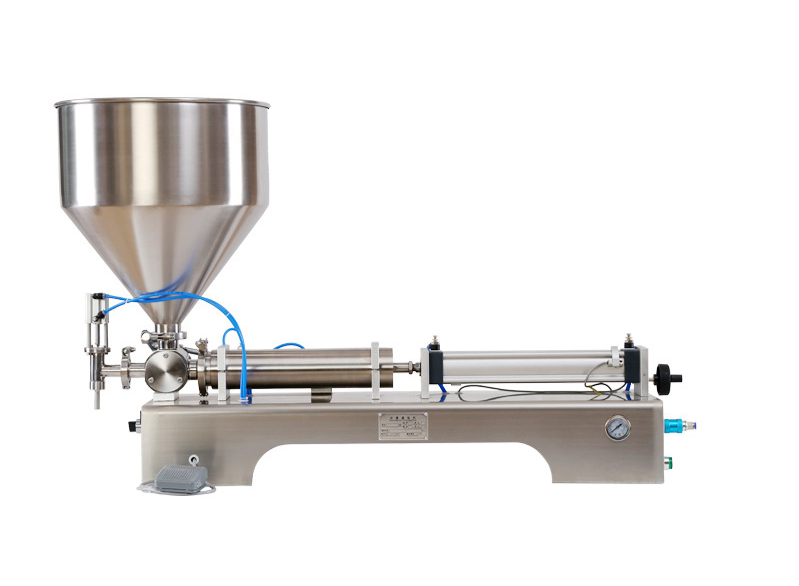

Semi-automatic Liquid Filling Machine

Semi - automatic Piston Liquid Filling Machine is engineered for efficient and precise filling of low to medium viscosity liquids in small - to medium - scale production environments. Built with high - grade stainless steel, it ensures longevity while meeting stringent hygienic standards for the food, cosmetic, chemical, and pharmaceutical industries. Its streamlined design, paired with intuitive manual or pneumatic operation, delivers adjustable filling volumes with high accuracy, along with easy - to - maintain features. As a cost - effective solution for applications ranging from sauces and oils to lotions and syrups, this machine balances reliability and affordability, making it ideal for international markets seeking entry - level automated filling capabilities.

-

0.000.00

-

Semi - automatic Piston Liquid Filling Machine is engineered for efficient and precise filling of low to medium viscosity liquids in small - to medium - scale production environments. Built with high - grade stainless steel, it ensures longevity while meeting stringent hygienic standards for the food, cosmetic, chemical, and pharmaceutical industries. Its streamlined design, paired with intuitive manual or pneumatic operation, delivers adjustable filling volumes with high accuracy, along with easy - to - maintain features. As a cost - effective solution for applications ranging from sauces and oils to lotions and syrups, this machine balances reliability and affordability, making it ideal for international markets seeking entry - level automated filling capabilities.

Product Details

Working Principle

The machine utilizes a piston - driven filling mechanism. Liquid is first stored in a stainless - steel funnel. When activated by a manual trigger or foot pedal, the piston moves downward to draw liquid into the cylinder. During the upward stroke, the piston forces the liquid through a nozzle into pre - positioned packaging containers. The filling volume is determined by adjusting the piston stroke (or via a calibrated dial), ensuring consistent dosing with minimal overflow. Typically featuring a single - head configuration, this design prioritizes simplicity and ease of operation.

Features

Robust & Hygienic Build:

Constructed with food - grade stainless steel, it resists corrosion and simplifies cleaning, aligning with global hygiene regulations.

User - Friendly Operation:

Intuitive manual/pneumatic controls require minimal training, making it accessible for small businesses or first - time operators.

Precision Filling:

Adjustable volume settings (via stroke or dial adjustments) maintain accuracy within ±1%, reducing material waste and enhancing product consistency.

Versatile Compatibility:

Suited for low - to medium - viscosity liquids across industries, including food sauces, cosmetic lotions, chemical solutions, and pharmaceutical syrups.

Cost - Effective Scalability:

Lower upfront costs and low - maintenance design make it perfect for labs, short - run productions, or businesses with limited budgets.

Technical Highlights

Core Technology:

The piston - based mechanism ensures precise volume control; pneumatic models (driven by air compressors) boost efficiency over purely manual versions.

Key Specifications:

Filling speed ranges from 10 to 40 bottles per hour; accommodates container heights of 80–300mm; power options include manual operation or a 0.4kW air compressor (0.4–0.6MPa).

Precision Enhancements:

A drip - proof nozzle and stroke - controlled dosing eliminate leakage, maintaining clean production lines and reducing post - filling cleanup.

Application Fields

Ideal for:

Food industry (sauces, edible oils, syrups, dairy products);

Cosmetics (milky lotions, essential oils);

Chemical industry (cleaners, solvents);

Pharmaceuticals (syrups).

It is also well - suited for laboratories, sample filling, and custom small - batch productions, addressing the demand for scalable, efficient filling solutions in international markets.

vAll machines can be customized to meet your specific requirements. Contact us for more details!

.png)

.png)