-

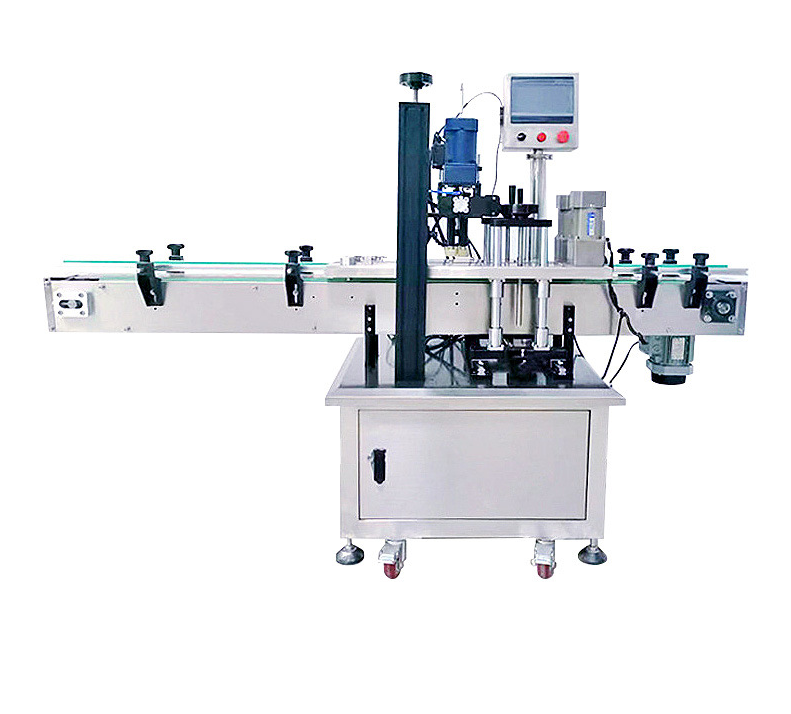

Rotary Capping Machine

Rotary Capping Machine is a high - efficiency automated solution engineered for precise and reliable capping operations across food, pharmaceutical, chemical, and other packaging - intensive industries. Leveraging a rotary design and PLC - controlled system, it delivers consistent capping quality while accommodating diverse bottle materials (plastic, glass) and cap types (screw caps, tamper - evident seals). With stable bottle handling, adjustable capping torque, and user - friendly operation, it is perfectly suited for medium to high - volume production lines, drastically cutting labor costs and enhancing sealing consistency.

-

0.000.00

-

Rotary Capping Machine is a high - efficiency automated solution engineered for precise and reliable capping operations across food, pharmaceutical, chemical, and other packaging - intensive industries. Leveraging a rotary design and PLC - controlled system, it delivers consistent capping quality while accommodating diverse bottle materials (plastic, glass) and cap types (screw caps, tamper - evident seals). With stable bottle handling, adjustable capping torque, and user - friendly operation, it is perfectly suited for medium to high - volume production lines, drastically cutting labor costs and enhancing sealing consistency.

Product Details

Working Principle

This machine operates on a rotary - style mechanism. Bottles are conveyed into the machine and precisely positioned via a bottle - handling turntable. Concurrently, the cap feeding system ensures smooth cap delivery to the designated location. Driven by servo motors (or air cylinders, depending on the model), the capping heads then screw caps onto bottles with precise torque control. Post - capping, bottles exit and proceed to the next process. The entire sequence is automated, with the PLC synchronizing tasks like bottle feeding, capping, and ejection to enable continuous, high - speed production.

Features

High - speed & Stable Performance:

Powered by servo motors and a robust rotary structure, it achieves capping speeds of 40 - 200 bottles per minute (model - dependent), ensuring stability during extended production runs.

Intelligent Control:

A PLC + HMI system allows intuitive parameter setting (e.g., capping torque, speed) and real - time monitoring. The fault detection system (e.g., for missing caps or misaligned bottles) triggers automatic alerts and machine stops, guaranteeing efficiency and quality.

Wide Compatibility:

It adapts to different bottle diameters (20 - 120mm) and cap sizes, working with plastic, glass, PET bottles, and various cap types (screw caps, sport caps, tamper - evident lids).

Durable & Safe Construction:

The body uses food - grade 304/316L stainless steel, meeting hygiene standards. Emergency stop buttons and safety guards ensure operator safety.

Low Maintenance:

Modular design enables quick disassembly and cleaning, minimizing downtime.

Technical Highlights

Drive System:

Servo motor/variable frequency drive for precise speed control and energy efficiency.

Control System:

PLC (e.g., Siemens/OMRON) + touch screen for stable operation and easy programming.

Pneumatic System:

FESTO/SMC - grade pneumatic components ensure reliable actions like cap feeding and capping head reset.

Technical Parameters (Model - dependent sample):

Capping speed: 40 - 120 BPM

Bottle size: Height 100 - 300mm, Diameter 20 - 120mm

Cap diameter: 15 - 80mm

Power: 1.5 - 3KW

Air supply: 0.4 - 0.6MPa, 100 - 150L/min

Dimensions: 1200(L)×900(W)×1500(H)mm (varies)

Compliance:

Optional CE certification for global market access.

Application Fields

It is widely used in:

Food (beverages, condiments, canned food);

Pharmaceutical (medicine bottles, oral liquids);

Chemical (lubricants, solvents);

Cosmetics (skin care, hair care) industries.

It supports capping operations on PET plastic bottles, glass bottles, aluminum bottles, and is compatible with screw caps, tamper - evident seals, and other common cap types.

As an essential component of automated production lines, it is ideal for mid - to - large - scale enterprises.

vAll machines can be customized to meet your specific requirements. Contact us for more details!

.png)

.png)

.jpg)