-

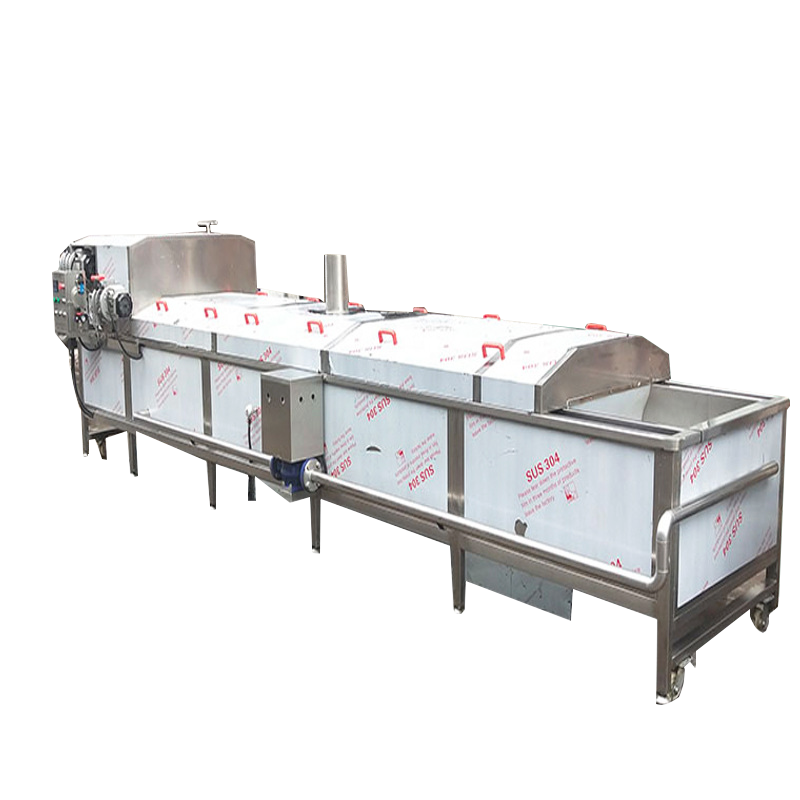

Bag-Type Water Bath Sterilizer

Bag-Type Water Bath Sterilizer is a specialized food processing solution engineered for efficient microbial inactivation in bagged food products. Utilizing precision water bath technology, it delivers uniform heat penetration to ensure thorough sterilization while maintaining product quality. Constructed with food-grade stainless steel, this equipment meets international safety standards (e.g., FDA, HACCP) and is designed for small-to-medium-scale manufacturers seeking reliability, energy efficiency, and easy operation. By extending shelf life and guaranteeing food safety, it has become a critical asset for global bagged food producers.

-

0.000.00

-

Bag-Type Water Bath Sterilizer is a specialized food processing solution engineered for efficient microbial inactivation in bagged food products. Utilizing precision water bath technology, it delivers uniform heat penetration to ensure thorough sterilization while maintaining product quality. Constructed with food-grade stainless steel, this equipment meets international safety standards (e.g., FDA, HACCP) and is designed for small-to-medium-scale manufacturers seeking reliability, energy efficiency, and easy operation. By extending shelf life and guaranteeing food safety, it has become a critical asset for global bagged food producers.

Product Details

Working Principle

This sterilizer operates via immersion of sealed food packages in a thermostatically controlled water bath. Heated to a preset temperature (typically 80–120°C), the water bath transfers heat uniformly to package surfaces, penetrating contents to inactivate bacteria, yeasts, and molds. A precision temperature control system (±0.5°C accuracy) maintains stability throughout the cycle, while a timer regulates sterilization duration. Post-cycle, the water cools or drains automatically, ensuring products exit at a safe temperature. This method ensures consistent efficacy for various bag sizes, shapes, and packaging materials (e.g., plastic pouches, aluminum laminate bags).

Features

Food-Safe Construction:

Built with 304/316L stainless steel, ensuring corrosion resistance and compliance with FDA/HACCP hygiene standards.

Automated Efficiency:

PLC or touchscreen controls enable easy programming of temperature, time, and cycles, with real-time monitoring and data logging for traceability.

Energy Optimization:

Insulated chamber design and recirculation pumps minimize heat loss, reducing energy consumption by up to 30% compared to non-insulated models.

Modular Design:

Compact, scalable footprint suits limited factory spaces; optional rack systems support bulk processing (200–500kg per batch).

Safety Protocols:

Includes over-temperature protection, emergency stop switches, and automatic leak detection for operation.

Technical Highlights

Temperature Range:

30–130°C with ±0.5°C precision.

Chamber Size:

Customizable (e.g., 1000mm x 1500mm x 1200mm) to support batch or continuous processing.

Heating Options:

Electric, steam, or gas heating systems with rapid heat-up/cool-down capabilities.

Drive Mechanism:

Variable Frequency Drives (VFDs) for smooth basket/rack movement, reducing product damage.

Certifications:

Manufactured to GMP standards, with optional CE/ISO certification for global market access.

Application Fields

Ideal for bagged food manufacturers across sectors:

Prepared Foods: Marinated meats, cooked vegetables, ready-to-eat meals (e.g., rice, stews).

Beverages & Dairy: Soy milk pouches, yogurt packs, fruit juices, and nutritional drinks.

Sauces & Condiments: Tomato sauce, chili paste, salad dressings in stand-up pouches.

Bean & Tofu Products: Vacuum-sealed bean curd, fermented bean pastes, and tofu packs.

By eliminating pathogens and spoilage microbes, this sterilizer extends shelf life up to 6–12 months without refrigeration, meeting demands for export and retail distribution.

vAll machines can be customized to meet your specific requirements. Contact us for more details!

.jpg)

.png)