-

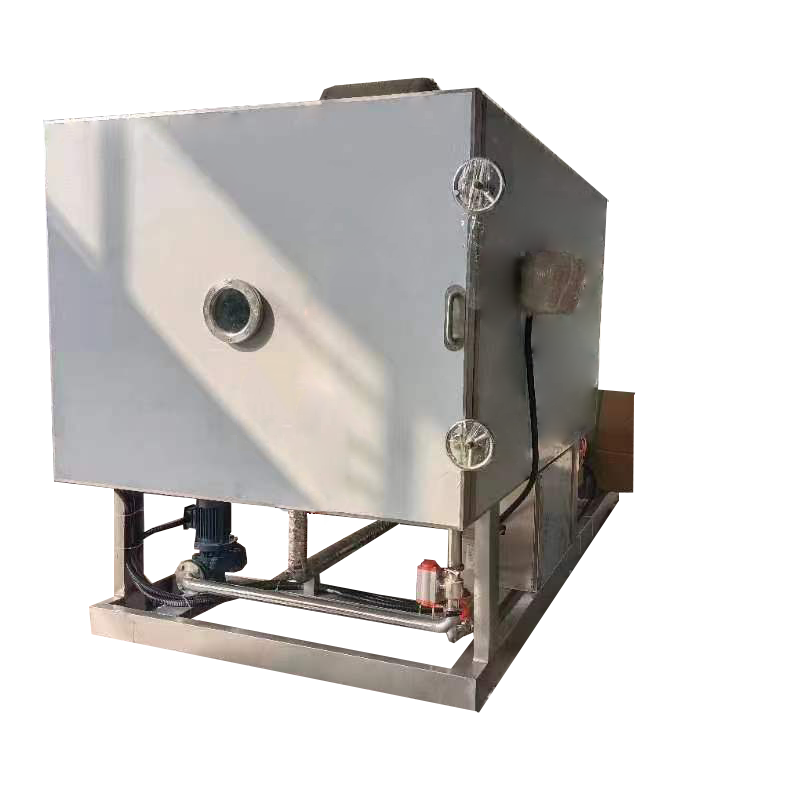

Square Freeze Dehydrator

Square Freeze Dehydrator is a cutting-edge food processing machine specializing in freeze-dehydration. Leveraging advanced lyophilization technology, it rapidly freezes materials below their eutectic point in a vacuum environment and then sublimates ice into water vapor. This process preserves the original texture, nutrition, and flavor of food. Constructed with food-grade stainless steel and powered by an automated control system, it ensures precise temperature management and stable performance. The multi-tray design supports large-scale batch processing, making it suitable for fruits, vegetables, meats, pet food and other food industries. It effectively extends shelf life and facilitates storage and transportation while complying with international food safety standards.-

0.000.00

-

Working Principle

The Square Freeze Dehydrator operates via the lyophilization process. First, pre-treated food is quickly frozen to temperatures below its eutectic point (typically-30°C to-50°C) in the freezing chamber. Then, under high-vacuum conditions (≤50Pa), the frozen water sublimates directly from solid ice to water vapor. The vacuum pump maintains the low-pressure environment, while the condenser (operating at-50°C to-60°C) captures water vapor and converts it into ice. After primary drying, a secondary drying stage removes any remaining bound water, resulting in dry products with intact cellular structures and minimal nutrient loss.

Features

Stainless-Steel Construction:

Built with food-grade stainless steel, it is durable, hygienic, and easy to clean, fully meeting food safety standards.

Intelligent Control System:

A PLC + HMI system enables precise temperature control (±1°C) and automated operation, significantly reducing labor costs and operation errors.

Multi-Tray Capacity:

The chamber is equipped with 10-15 customizable trays, supporting high-efficiency batch processing and large-scale production.

Energy-Efficient Technology:

The cascaded refrigeration system achieves ultra-low temperatures while saving energy, and the fast cooling rate improves production efficiency.

Wide Adaptability:

It can be adapted to various food types, and customized drying curves can be set for different materials to ensure the best drying effect.

Technical Highlights

It integrates core technologies such as vacuum freeze-drying, PLC automation, and cascaded refrigeration.

The vacuum system ensures smooth sublimation, and the HMI interface allows real-time monitoring of parameters like temperature, pressure and time.

The refrigeration system uses environmentally friendly refrigerants, and the structural design optimizes heat transfer and vacuum distribution, ensuring uniform dehydration and stable product quality.

Application Fields

It is widely used in multiple food processing fields. For fruits like strawberries and mangoes, it can retain their color, aroma and taste; for vegetables like onions and spinach, it can retain their nutrients and rehydration performance; for meats and seafood, it can extend their shelf life to 3-5 years; for health products such as extracts, it can retain active ingredients; for pet food, it can improve palatability and nutrition. In addition, the processed products are easy to store and transport, making them ideal for export, emergency rations and high-end processed foods.

vAll machines can be customized to meet your specific requirements. Contact us for more details!

.png)

.jpg)

.jpg)

.jpg)